One of the standard rites of passage during a electrical engineering student’s time at LeTourneau is the Rube Goldberg demonstration which is a part of Electronic Design Lab, also known as ELAB III. This course contains a variety of requirements which are separated into modules, labs and lab reports, mini-labs, and quizzes and tests. 65% of your course grade depends on the lab reports and modules. These modules are projects that the student must individually design, build, and demonstrate such as a DC power supply, a function generator, and a 10 watt power amplifier and the labs cover material from RC and RL transients to transmission line theory. The other 35% of the class is distributed between quizzes, the final, and a few other small assignments.

One of the most enjoyable and yet exhausting modules/labs was the Rube Goldberg demonstration which is held each April. The goal is to design and construct a machine which accomplishes a trivial task through a long, strung-together series of transitions. As our group of three began to brainstorm ideas for our machine, we settled on a musical journey, noisily progressing towards the finale, popping a large balloon.

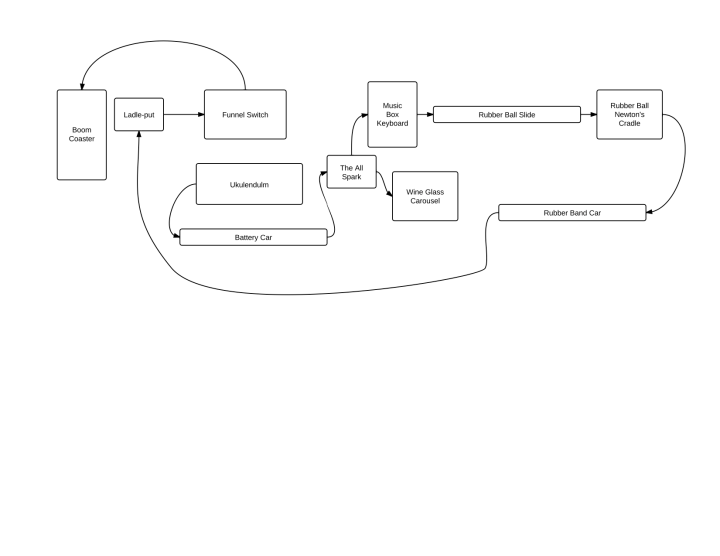

The steps were as follows:

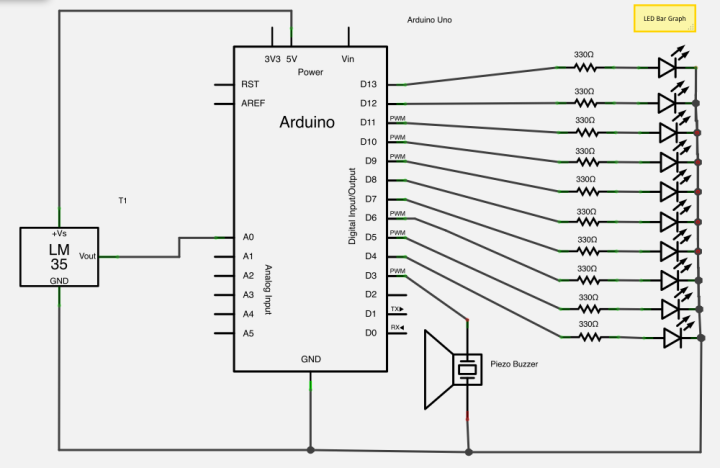

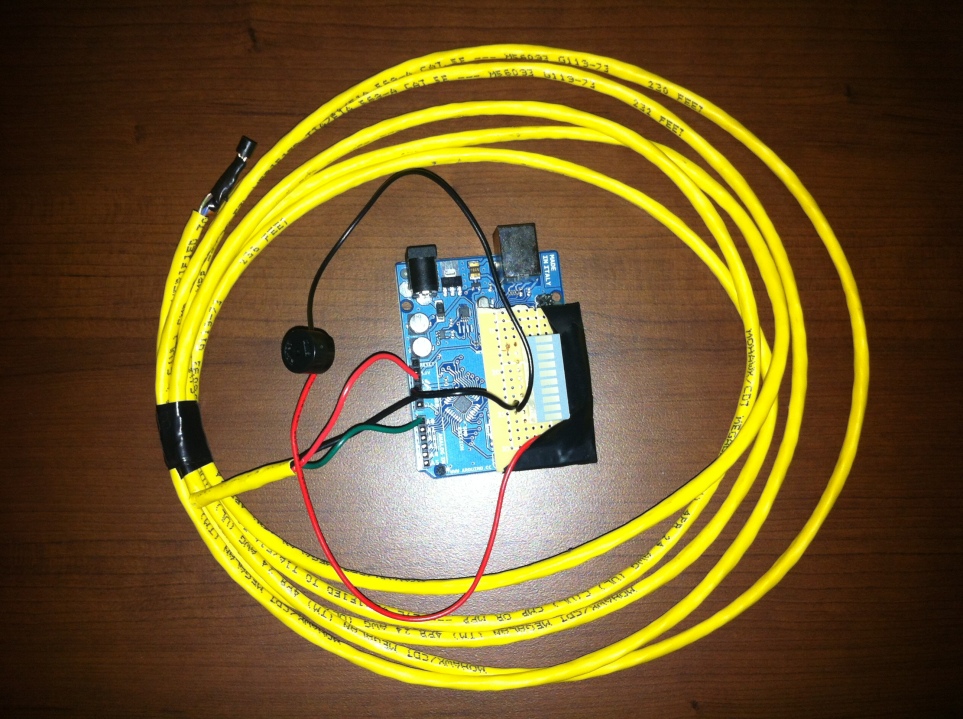

First, the ukuledulum, a ukulele suspended from the gym ceiling, swings over a distance sensor which produces a clicking sound like a metronome when the ukulele reaches the bottom of its swing. After 5 clicks, the Arduino connected to the distance sensor sends an infrared signal to trigger the car which is waiting on a set of rails. The car travels down the rails, crashing at the end into a bump switch which triggers a set of relays and turns on the music box keyboard and the wine glass carousel. These begin playing and a string winds around the spindle of the music box keyboard and ultimately pulls out a magnetic switch which releases a ball, sending it sliding down the metal ramp and crashing into the oversized Newton’s cradle at the bottom of the slide. The transition from the Newton’s cradle causes the last ball in the cradle to press a limit switch and trigger a rubber band car via infrared. This car again travels down a set of rails and crashes into another switch, triggering the razor-blade cutting machine which slices the string which keeps the ladle-put set to fire. After the razor-blade cuts through the string, the ladle-put releases, catapulting a ball into a large plastic tablecloth funnel. The ball then travels down into a cup at the bottom of the funnel, striking a switch which activates the mini-knex boom coaster equipped with needles. The coaster travels down and around its rails and pops the balloon, ending the musical journey with a large bang. Below are pictures of the different parts and finally a video of the entire machine. Hope you enjoy seeing the results of our project. Feel free to share with others!